Cha Yau Sponge Enterprise Co., Ltd., Cha Yau in short, is the biggest manufacturer of EVA foam mats, sport mats and related products in Taiwan. Since the demands of EVA foam products have increased and the market has still expanded, there will be more waste after the production. In that light of this, Mr. Kao Yung Hsin, the president of Cha Yau, and Mr. Kao Chien Chuan, had started to research how to convert the waste to the useful recycled material.

As we all know, to recycle the EVA waste has been not easy. There will be a dangerous reaction of the peroxide chemical that is in the EVA waste, if the converting is not well. Furthermore, the percentage of using recycled EVA waste has been very low. If you use to many EVA waste material in the mat, the physical properties will be down. That’s the reason why EVA recycled pellets cannot be accepted and used by most EVA manufacturers. Therefore, the EVA foaming waste has always been a hot potato until now. The only way that the factories can choose is to pay to the recycling company for handling the waste. This way not only increase the cost, but also affect the environment. (Normally, the recycling company is just to burn the waste or to bury it.) However, Taiwan environmental regulations have become stricter and stricter. This causes to the price of recycling has become higher, the worse is that the recycling company reject to take the waste. The EVA foam waste has become a big monster to block the business of producing EVA foam products in Taiwan.

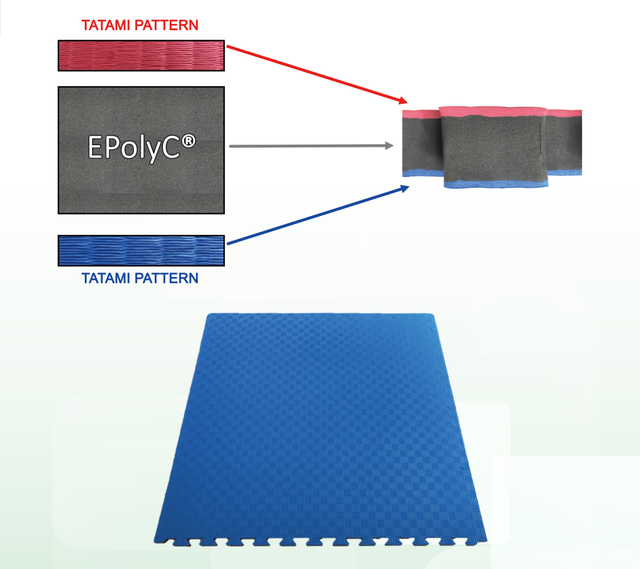

Fortunately, due to Mr. Kao Yung Hsin’s and Kao Chien Chuan’s efforts and research, they finally found a solution to eliminate the chemicals in the EVA foam waste. In addition, they also developed the new renewable raw materials through Cha Yau’s unique remanufacturing technology. The new material we named “ EPolyC®”. Meanwhile, Mr. Kao Chien Chuan updated the EVA foam formula and improve the processes of production to raise the usage percentage of EPolyC®. We can add the EPolyC® into the EVA foam mats to 50%. Besides, to use EPolyC® instead of a part of the filler can make the mat firmer and solider. Not only that, the compression set of the EPolyC® mat is better than the normal one and the mat has the certification of EN71. The best is, EPolyC® material already passed the REACH test. It is really the safest and best solution to the EVA foam waste.

The benefits of EPolyC® Mat are as follows,

1. EPolyC® passed the REACH test.

2. The Mat with EPolyC® has the certification of EN71.

3. Good Quality.

4. Better Physical Properties.

5. More Competitive Price.

Cha Yau Enterprise Co., Ltd. has developed a safe and reliable EVA recycling and re-granulation that can be added in large quantities, and can improve the strength of the product. The main purpose is to protect the environment and our next generation and take up corporate social responsibility. So that Taiwan's EVA industry can develop sustainably. Cha Yau will continue to innovate, develop, and create recycled value for EVA waste. Not only that, we will continue to improve the production technology in the future. We must improve ourselves to own advantages and face to the international competitors, and be at the forefront of all EVA foaming factories.